After I finally got around to lifting my 2018 Jeep Wrangler JK Unlimited Rubicon (30 months of ownership) with a Metalcloak 2.5″ Game-Changer Rocksport suspension lift kit, I said I would ride around on the factory 32″ tires for a while.

Well, that mindset changed very quickly.

Three weeks later, I ended up getting the 35″ tires and new wheels in the form of the Milestar Patagonia M/T LT315/70R17 and the Icon Alloys Vector 5 (in satin black).

I had not expected to spend money on new tires at least for another 10K to 15K miles since my factory BF Goodrich KM LT255/75/R17 (32″) tires still had 11/32″ tread depth on them (19/32″ new).

But given that I wore down 8/32″ of the treads after 24K miles in 28 months and the current COVID-19 situation that has slowed down my Jeep mileage significantly, odds are I wouldn’t be getting new tires (assuming I replace due to completely worn tires) for another 12 months at the earliest.

With that in mind and wanting tires a little sooner than that, I called up a local tire shop that I have been to a couple times before for my other vehicles and got a quote on the Milestar Patagonia M/T LT315/70R17 and Icon Alloys Vector 5 (in satin black). The price was decent for a set of five (5) so I pulled the trigger.

As to my selection of tires and wheels, I knew I wanted to go with 35″ tires because it gave me more ground clearance over the stock 32″ tires for the light to medium off-road terrain that I go through. I didn’t want to go to 37″ tires because of the added overhead necessary to run such a larger tire (stronger axles and axle components) along with the higher costs.

I do like the BF Goodrich KM-series of tires and with the release of the KM3 (third generation in the KM Mud Terrrain line) over a year ago, I thought I would be getting the KM3. But after reading a lot about the Milestar Patagonia M/T and seeing the lower price point per tire, I decided to risk my money on the Milestar tires.

Note: Milestar refers to the M/T in Patagonia M/T as Maximum Traction and not Mud-Terrain. But most people accept this as a Mud-Terrain class tire (as opposed to an All-Terrain tire).

Milestar does not make the Patagonia M/T in a 35×12.50R17, but instead sells the metric equivalent in the form of the 315/70R17, which is what I selected.

As far as the wheels, I actually had a hard time finding a 4.5″ backspaced wheel that I liked. I did not want a wheel that had the faux-beadlock appearance (bolt heads around the lip of the wheel). Furthermore, I had my own personal requirement of getting a wheel with a 71.5mm bore to maintain hub-centricity for that centering support on the hub.

After a lot of browsing of manufacturer websites, I initially selected the Fuel Off-Road Nitro 5. But I later watched a recent TrailRecon video where a lift kit was installed on a TJ, and in that video they mentioned the Icon Alloys Vector 5 wheel, so I checked out the Icon website and found that the Vector 5 fit the bill exactly (4.5″ backspacing, 71.5mm hub bore diameter) and I liked the design more than the Fuel Nitro 5.

So thanks to TrailRecon, I changed my decision on the wheel to the Icon Alloys Vector 5 in satin black.

I know that a lot of people immediately throw bigger tires (and new wheels) on a Jeep Wrangler after they get acquire the vehicle. With the Jeep Wrangler JK, larger tires actually presents a lot of issues that people don’t account for.

First off is the wheel and tire clearance. You pretty much need to lift a factory JK to install anything bigger than 32″ tires. You can go with a 33″ tire with the stock suspension height, but there will be rubbing of the tire when driving off-road and potentially on-road when in a full turn. Going with a lower backspaced wheel will help (factory JK backspacing is 6.25″), but the potential for tire and/or wheel contact with the suspension, steering, and/or undercarriage is high.

Note: The Wrangler JL generation has some slight improvements over the JK with regards to running larger tires. As far as I know, all Wrangler JL trims can run 35″ tires with a stock suspension for on-road use. With off-road use, a 2″ lift is required with 35″ tires.

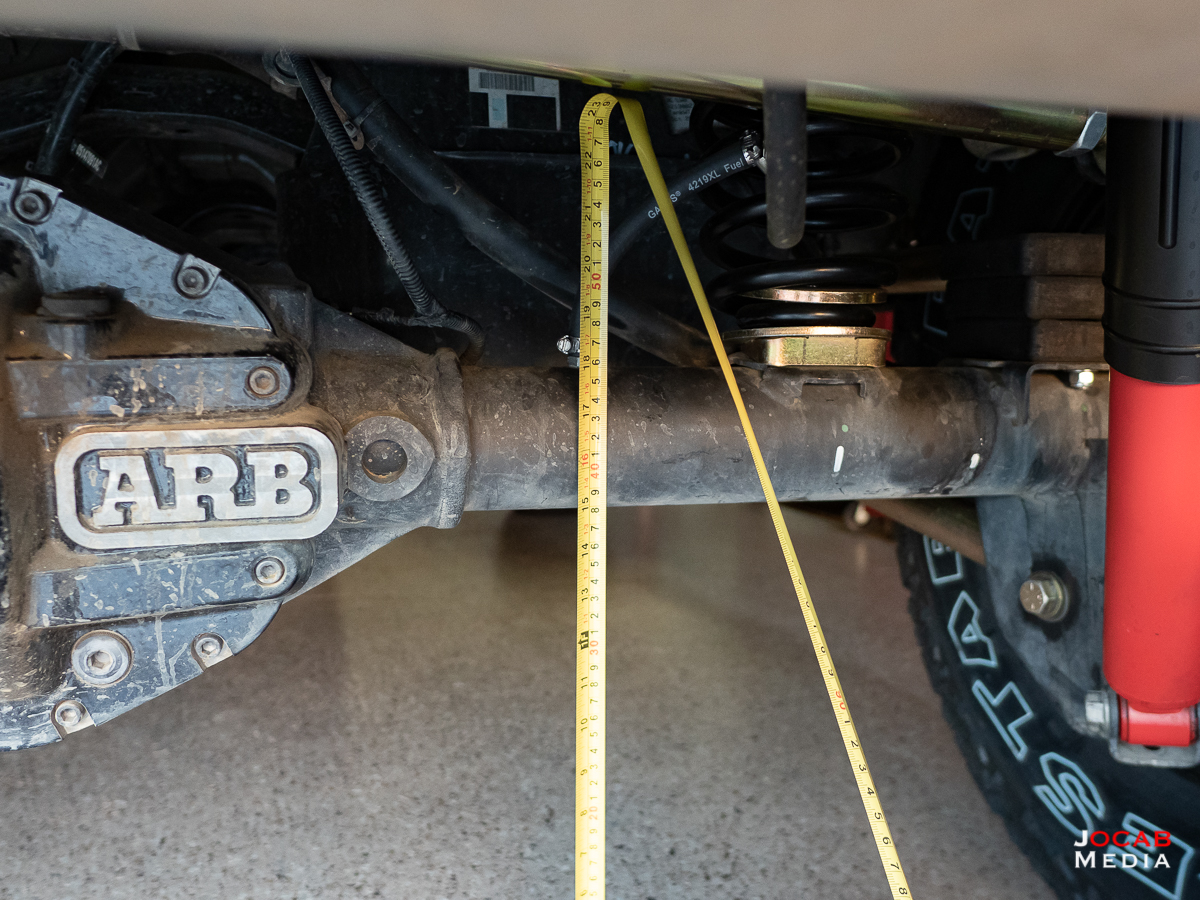

Even with a lift kit, larger tires with the factory backspace wheels can rub suspension components. Thus, a second item to account for is lesser backspaced tires. 4.5″ backspacing is the defacto standard with 35″ tires on a JK and this should prevent any sort of rubbing of the tire or wheel against suspension components. Along with wider tires, this will result the tires to protrude farther out from the vehicle.

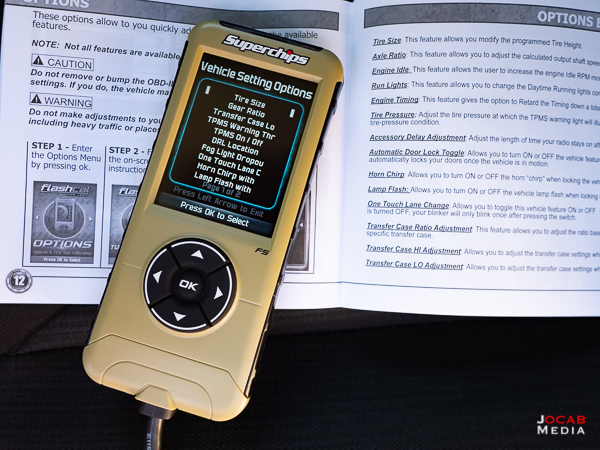

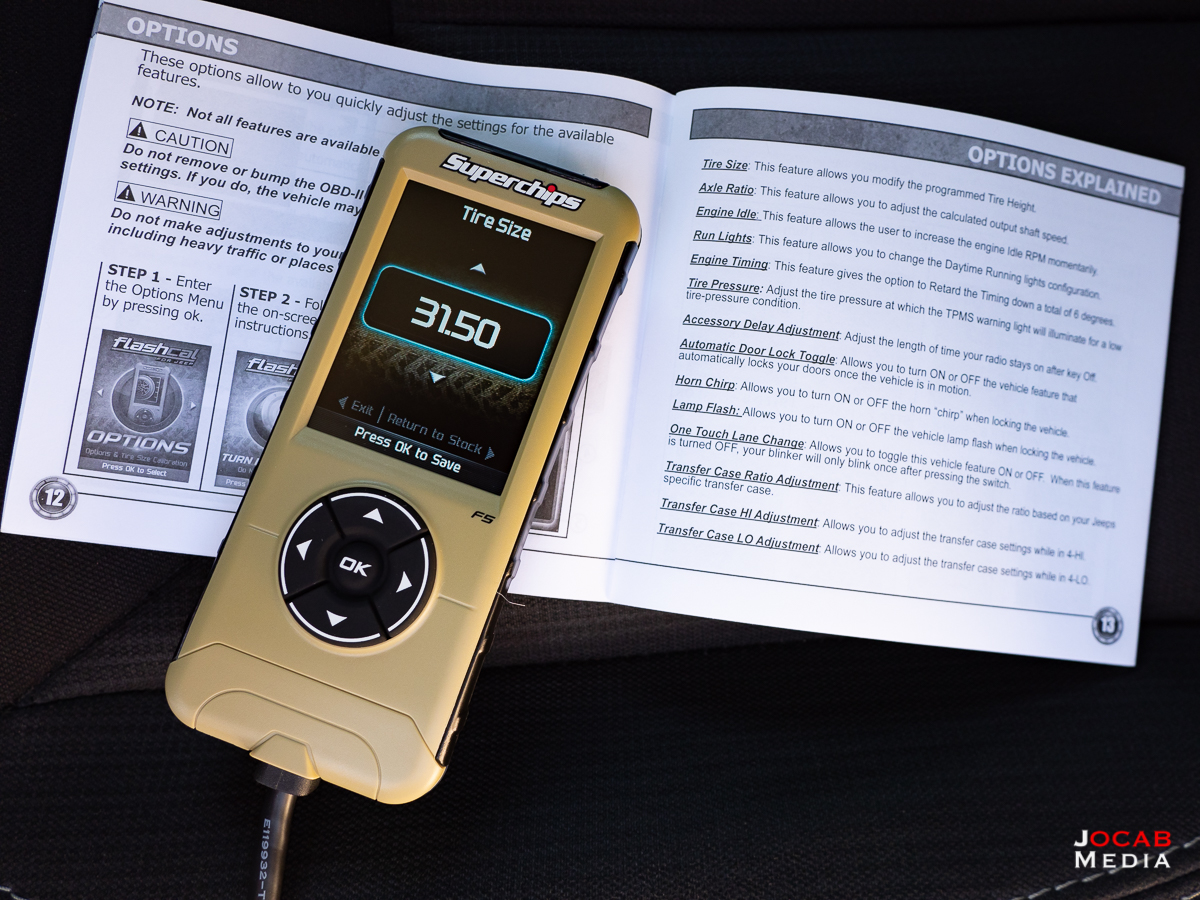

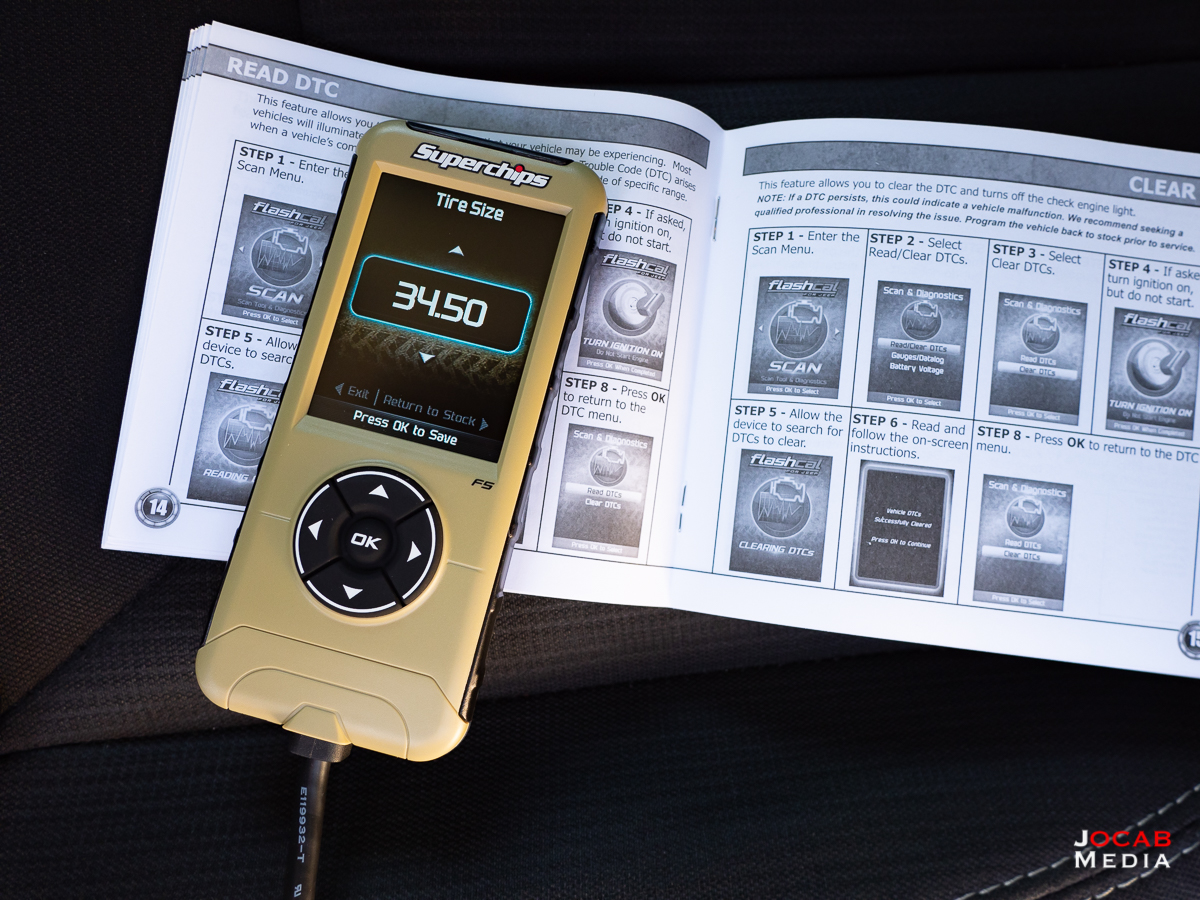

A third issue to account for is the speedometer correction. Going with a larger tire will cause the vehicle computer to think you are going slower than your actual speed. This requires reprogramming of the ECU. Thankfully, there are programmers out there on the consumer market to allow owners to correct this. I acquired a Superchips Flashcal F5 (for JK) to reprogram the tire size setting in my Jeep from factory to aftermarket.

Note that the computer was actually set from the factory with a 31.5″ configuration with 32″ (255/75R17) tires. This is because a tire is actually smaller in diameter when mounted on the wheel and installed on a vehicle under the load/weight of the vehicle. With that in mind, I set the configuration with the new 315/70R17 to 34.5″.

After a little bit of driving on some flat straight roads on cruise control, I ended up truing the tire size to 33.75 which appears to be in line with the live GPS speed data (Waze). I may even drop it down to 33.50 after a little more driving to provide a larger sampling of data.

Another issue to account for with larger tires specifically on a JK Rubicon is the factory Rubicon rock slider. For some reason the rear portion of the JK Rubicon rock slider extends into the wheel well, unlike the front portion which ends flush with the wheel well.

While the straight vertical looks like there might be enough gap, the way the wheel can articulate while driving on off-road terrain will result in rubbing of the tire against the factory rock slider.

The ideal solution is to get an aftermarket rock slider (preferably one that is more robust and frame mounted). I elected to go the less expensive (and common) route for the time being and trimmed 1.5″ off the rear section of the factory Rubicon rock sliders. The rock sliders are hollow with approximately 3.5mm thick steel (slightly thicker than 1/8″) so you should be able to make quick work of them with a cutting wheel on an angle grinder or cut off tool.

IMPORTANT: I did remove the rocker sliders from the vehicle in order to cut them. Some people leave them on, but why risk damaging the body and/or paint with the cutting wheel or sparks? There are three (3) bolts and six (6) nuts holding each slider on and the sliders are easy to remove.

After the trim, I now have plenty of clearance for the rear tire to travel without making contact with the factory Rubicon rock slider.

One often overlooked issue after acquiring larger tires is the spare tire carrier. Many people still use the factory spare tire carrier which is only rated to hold 85 pounds. I didn’t get a true weight of my new tire and wheel combination, but based on factory specifications the tire is 67.92 lbs and the wheel is 30 lbs for a total of 97.92 lbs.

Fortunately for me, I run an aftermarket spare tire carrier that is mounted to the rear bumper in the form of the LOD Offroad Destroyer rear bumper and tire carrier system, which has a 300 lb maximum load limit.

Note that I did have to make adjustments to my LOD Offroad tire carrier setup moving from the 32″ tires with 6.25″ backspaced wheels to 35″ tires with 4.5″ backspaced wheels.

I pretty much shifted the tire carrier bracket vertically one notch up to bring the whole wheel and tire a little higher (so more of the tire makes contact with carrier; tire needs to squeeze against the tire carrier) and moved the bracket inward (less backspacing). I also swapped out the tire carrier bracket bolts from the grade 5 bolts that were included with the bumper and carrier system to grade 8 bolts.

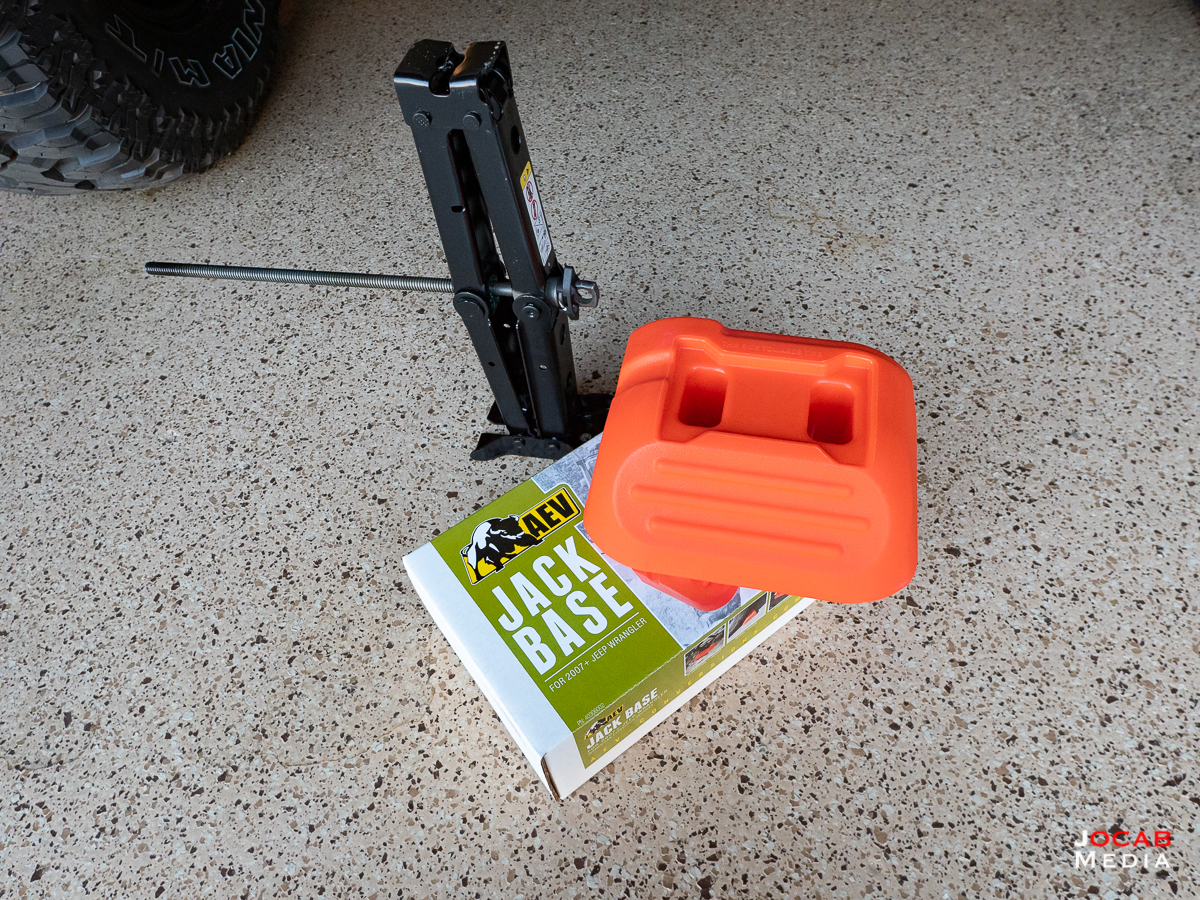

An increase in tire size also brings about a new requirement for emergency tire changes. The factory scissor jack in Jeep Wrangler JKs may not have enough height to change a 35″ tire depending on the installed diameter of the tire.

So this means that if you get a flat or other tire malfunction while out and about, you need a way to jack up the vehicle higher than the factory emergency jack elevate.

Hi-Lift jacks (or farm jacks) are a go to for many because they have the ability to elevate a vehicle very high and they have become synonymous with off-road recovery. But Hi-Lift jacks have some inherent safety issues when used improperly and can still be dangerous when properly used, so many people opt for safer options like bottle jacks.

In my case, I actually used to carry a Hi-Lift Xtreme 48″ jack on my rear tire carrier but stopped doing so because of the added noise when driving. I relegated it to the garage until I needed it for an off-road excursion.

I ended up just selling the Hi-Lift jack and going with the AEV JK jack base which is a safe way to elevate the factory scissor jack an additional 3.5″ off the ground which will allow the scissor jack to be used with 35″ (or even 37″) tires.

I did attempt to jack up my JK with the new wheel and tire combo using the scissor jack without the base and I was able to just barely get the tire off the ground (less than 1″).

So I probably could get away with the factory scissor jack for an emergency tire change, but if off pavement, this is probably going to be a little sketchy given soft, uneven ground. Thus, the AEV JK jack base provides more stable scissor jack condition and guarantees the tire can get off the ground.

Tip: If off-road and needing to jack the vehicle higher than the jack allows to change a tire, dig a hole and get Jeep parked with the flat tire in the hole and proceed to jack up vehicle.

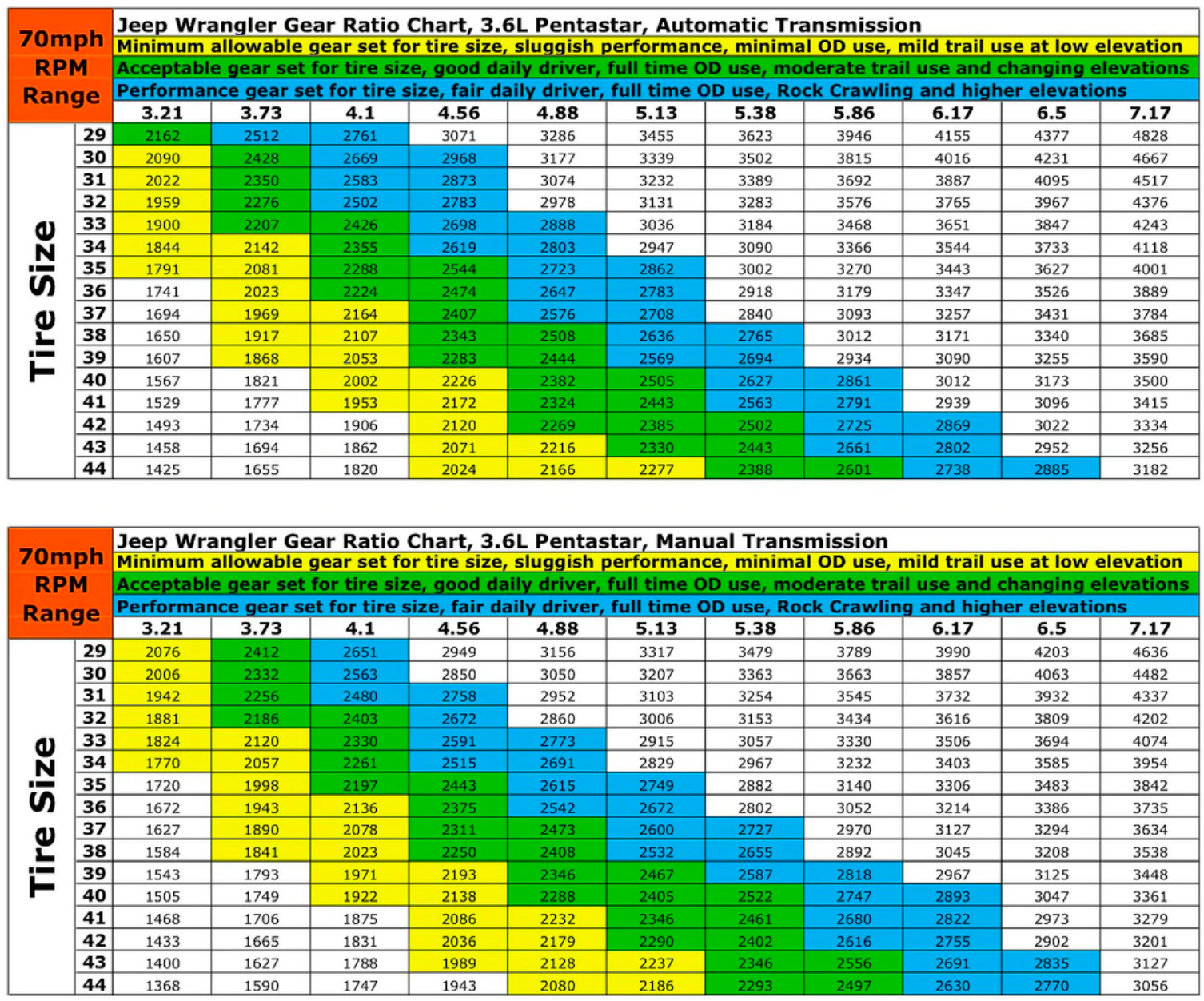

The elephant in the room when upgrading to larger tires is axle gearing. The large majority of people that upgrade to larger tires do not bother with regearing their axles. The problem with not regearing is that the vehicle engine is not going to perform like it did with the original tires. There will be a loss in power across the entire RPM band. From a practical viewpoint, the driver will notice that the vehicle is sluggish and less responsive than before.

Here is a visual comparison of my Jeep before and after the new tires.

As you can see, there is a 241 RPM drop at 70mph when I swapped out for the 35″ tires.

NOTE: After I did more tire size / speedometer truing, it appears that the RPM at 70mph is closer to 2400.

In order to get the responsiveness back, I need to change out the factory Rubicon 4.10 gears for shorter gears. The off-road shop that I took my Jeep to for my alignment after I installed my lift kit quoted me $1400 for a regear (parts and labor) which is on par with a couple of other reputable shops in the Southern California area. They also helped to convince me that I should look to go with 4.88 gears (and skip 4.56) with 35″ tires.

There is a chart on that has been well disseminated within the Jeep community to aid in gear ratio selection.

Given this chart, we can put my original 32″ tires in the 31″ x 4.1 cell on the table which is 2583 RPM (close to the ~2600 RPM I was seeing in actual driving). 4.56 gears will probably get me exactly to where I was before, but 4.88 gears will get me around 2800 RPM at 70mph, which is about a 200 RPM increase over stock.

This will hurt fuel efficiency even more, but I feel like I want just a little more responsiveness over stock. The acceleration of my Jeep with the factory 32″ tires and 4.10 gears was decent, but I felt like it could use just a bit more kick from dead stop (or slow rolling speeds).

Granted, the benefit of the larger tires with a higher gear ratio is better gas mileage, especially on highway/freeway. But no one buys a Jeep for the fuel efficiency.

After driving the Jeep with the new wheels and tires, I definitely plan on getting new gears before the end of the 2020. As mentioned earlier, I plan on going with 4.88 gears. But what I kind of want to do when the new gears are installed is to also swap out the ball joints for something more robust and replace the front axle shafts with chrome-moly axle shafts.

Assuming $1400 for the regear (parts and labor), I’m going to be adding at least another $1400 just for the new axle shafts and ball joints (looking at Dynatrac rebuildable ball joints). It makes sense to swap out ball joints with a regear since the axle shafts have to come out anyway. But we’ll see if I want to commit another $3K to do all of this or if I just go with the regearing only.

I have not tuned my bump stops, yet. I have 3 out of 4 of the Metalcloak bump stops on each of the four corners. With 35″ tires and the factory fenders, Metalcloak recommends 4″ of bump stops (each bump stop is 1″ thick). Assuming I trim the fenders or buy aftermarket fenders, Metalcloak’s reference chart indicates 3″ of bump stops is adequate. I could trim my fenders to save money, but the tires as they are on these wheels are already protrude beyond the factory flares.

Trimming would make those tires extend out farther past the fenders, which I don’t really want so as to not sling debris from the treads on to the side of the Jeep. I don’t mind mud, but I tend to pick up lots of rocks when I drive to my shooting ranges, and flinging those rocks against the side of the Jeep while getting up to highway speed is not ideal.

We will see where I go as far as fenders. I am leaning towards the MCE fenders since they are made out of plastic (polymer) to not add additional weight, yet are flat-style for maximum clearance.

Anyway, that is a long discussion about the new Milestar Patagonia M/T LT315/70R17 tires and Icon Alloys Vector 5 satin black wheels that I put on my 2018 Jeep Wrangler JK Unlimited Rubicon. There are plenty of resources out there explaining what it takes to put larger tires on a Wrangler JK, but I figured it would make a nice write-up to discuss how I tackled (or will need to tackle) those issues.

Comment on this post