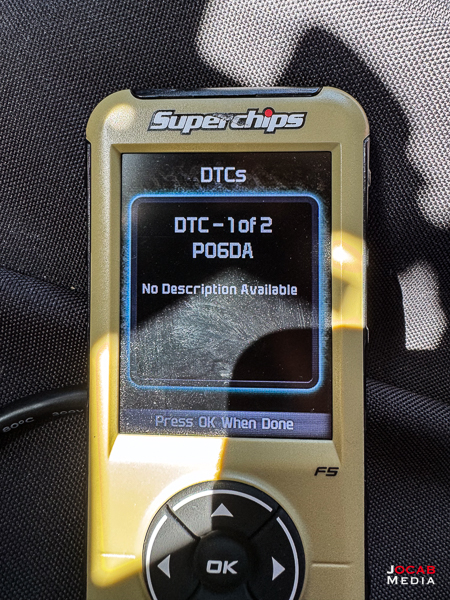

I was leaving my shooting range one day and started up Jeep and right when I was about to shift into gear the Check Engine Light came on. I checked the code and it showed P06DA.

For those who want to skip the story, the solution to the P06DA code in my situation was replacing the oil pump solenoid. If you want more details, read on.

The code reader I keep in the Jeep didn’t have a description and since the CEL wasn’t flashing and the vehicle was not in limp mode, I drove it out of the range and once I got to cell signal I checked Google to find P06DA typically refers to the engine oil pressure control circuit. I was watching my oil pressure and it was showing pressure, so I drove home. I was watching the oil pressure and it was running a little high on the freeway at cruising speed at around 70 PSI and still got down to about 22 PSI at full stop idle.

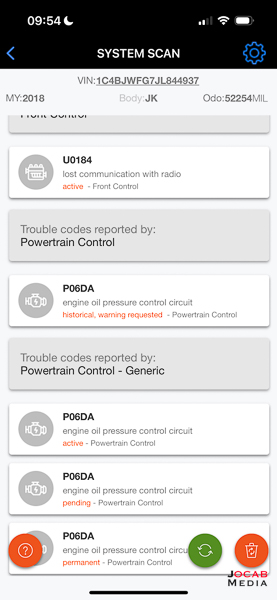

When I got home, I checked with JScan (phone app) as I keep the OBD2 bluetooth connector in my garage and it confirmed P06DA “engine oil pressure control circuit.”

With a lot of Google searching, there was inconsistent information on a P06DA. I did not find much specifically related to the Jeep Wrangler, but found a lot more with other vehicles with the 3.6L Pentastar engine. A lot of the discussions found online indicated P06DA with another P06D_ code would likely be the oil pump. However, a lot of discussions on P06DA by itself called for replacing the oil pressure sensor.

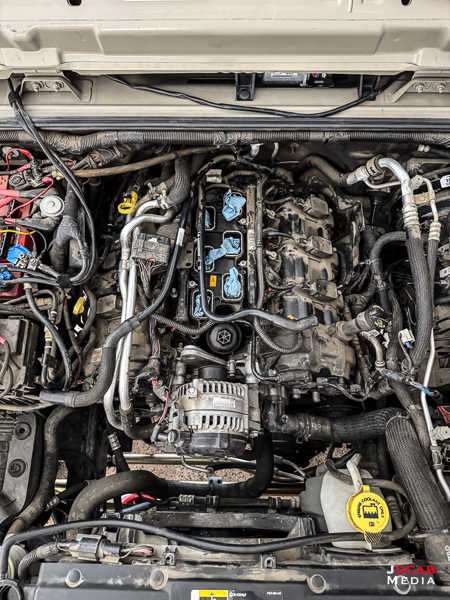

I ended up deciding to go this route first, but this required getting to the oil filter housing, which is infamous for being a tedious job on the JK because it requires removing the intake manifold. The oil pressure sensor is located on the oil filter housing.

For those that need to get to the oil filter housing on a Jeep JK 3.6L Pentastar, the reason why this is such a tedious job is simply because of all the hoses and lines that run on both sides of the intake manifold. All of these hoses and lines are anchored to the manifold or brackets around the manifold, and there are brackets that have to be removed in order to get the manifold off.

I used a couple of videos as reference for the process, which helped out tremendously.

Furthermore, I highly recommend having multiple ratchet extensions of various lengths, as it will help you out as you navigate the manifold removal.

When I got the oil filter housing exposed, I ended up replacing it with a brand new Mopar oil filter adapter (often referred as the oil filter housing) as I saw oil residue on the top side of the oil filter neck between the neck and the oil cooler. There wasn’t a valley filled with oil or coolant, so it was not a significant issue. But since I was already there, I decided to just replace the OFA, along with a new oil pressure sensor and a brand new transmission temperature sensor.

Note that I also replaced the spark plugs. My Jeep only has 52K miles on it, but again, I figured that since I am in there, I may as well just replace the spark plugs.

I reassembled everything, cleared the codes, and started up the engine. All was well with no leaks and I took it for a drive to get the ECU to collect data. I kept an eye on the oil pressure as I drove and it was behaving the same as before with a slightly higher than expected pressure at 55 mph cruising load.

When I got back home and in the driveway, I turned off the engine, waited a minute, and then restarted the Jeep. 5 seconds later the CEL lit up again. I checked the codes and it was still the P06DA.

After even more research, the next thing I decided to tackle was the oil pump solenoid. The oil pump on the 3.6L Pentastar is a two-stage pump that uses an electronically controlled solenoid to switch between low and high pressure based on the throttle and RPM. So aside from the oil pressure sensor, this is the only other thing that makes sense. I thought about replacing the oil pump, but since the oil pump is working as intended, I felt the solenoid was the route to go.

Strangely enough, Jeep (Mopar) does not sell the oil pump solenoid as a standalone part and requires purchasing a complete oil pump. Fortunately, Dorman manufactures the replacement solenoid (part number 926-235).

Accessing the oil pump solenoid on the oil pump itself requires removal of the upper oil pan. This is actually a straightforward task with 26 bolts and studs to remove and prying the upper oil pan off (sealed with RTV).

I found a good video on YouTube for referencing the process of the oil pump solenoid replacement.

After I reinstalled the new solenoid and upper oil pan (and put in new oil), I did the same test drive as before getting it to speed for a few miles. I noticed the oil pressure was now on the lower / normal end at 55 mph cruising load with around low 40s PSI.

When I got home from my test drive, I killed the engine, waited a minute and restarted the Jeep. Those 5 seconds after starting the engine again were heart thumping and the stress was alleviated as time passed with no Check Engine Light.

So after going through the arduous process of getting to the oil filter adapter/housing, my problem existed on the bottom not top of the engine.

While I was frustrated to see the CEL after replacing the oil pressure sensor, in the grand scheme of things I was not wasted time and effort as I did replace the oil filter adapter which may have been leaking at the neck, and I was able to take the opportunity to replace the spark plugs, which are high quality (NGK) plugs that will most likely last 100K.

If you ever get the P06DA code, I highly recommend going straight to the oil pump and replace the oil pump solenoid. While other information on the Internet points to the oil pressure sensor, I feel like the engine oil pressure control circuit message is more likely going to be the solenoid and this is what controls the oil pressure (the 2-stage oil pump), not the oil pressure sensor. Even if this ends up not being the issue, getting to the oil pump is less work than getting to the oil filter adapter.

Addendum: I figure I should post an update to this article as it is being referenced more often as of late. Four months and 2200 miles after I changed the oil pump solenoid (May to September), I got the same check engine light and DTAC of P06DA. Oil pressures were behaving similarly to when I first got this code, with cruising pressure of around mid 70 PSI.

I ended up acquiring the complete Mopar oil pump (68252670AP) and replacing the whole oil pump unit (which also includes a new solenoid).

I am now approaching four months after the oil pump replacement with close to 2000 miles driven. Hopefully the issue does not pop up, again.

Comment on this post