In Part 2 of Cleaning Firearms, The How for the AR-15, I went into detail on the five (5) phases of cleaning the AR-15, including cleaning the barrel and bolt carrier group. I mentioned a lot of cleaning tools and supplies in the context of my procedures for cleaning the AR-15, but left a lot of details out regarding other tools and supplies.

I wanted to continue discussing “The How” by listing the various cleaning tools and cleaning supplies I use for AR-15 cleaning, and some of the reasons on why I use those items.

Tools

- 20 caliber Pro-Shot stainless steel 36″ cleaning rod with 20 caliber Pro-Shot pierce-style jag

- 22 caliber Dewey nylon coated 36″ cleaning rod (Model: 22C-36)

- Lucas Bore Guide with 20 caliber and 22 caliber sleeves

- Dewey chamber cleaning rod (Model: CHR)

- Brownells AR-15 Bolt Carrier Scraping Tool

- Sinclair International Cleaning Cradle

First and foremost, I use a cleaning rod, and have always used a cleaning rod to clean a barrel.

There is a large contingency of people that use a cord/cable pull through type of bore cleaning tool such as the Hoppe’s BoreSnake or the Otis cleaning system. I have no problem with the Otis cleaning system. It’s actually a nice field portable and field expedient kit to have whenever cleaning is needed, but a cleaning rod is not feasible to carry around.

As far as the Hoppe’s BoreSnake, I don’t have a problem with a BoreSnake as much as I have a problem with how people use them. Generally, people will pull a BoreSnake through the barrel a few times and then call it clean. Sometimes they’ll spray some solvent onto the BoreSnake brush region, or into the bore, when they pull the BoreSnake through the barrel.

But that’s it. Then the next time the person decides to clean the gun, that person will take that same BoreSnake, and pull it through again. The problem? The BoreSnake is dirty from the last time it was used, and it continually getting more dirty. Very few people wash a BoreSnake, and even then, they don’t do it often. You don’t reuse a dirty cleaning patch repeatedly. The same applies to a BoreSnake.

That’s just my opinion. I know people are happy with BoreSnakes and never touch a cleaning rod. But that’s not me.

Now with a cleaning rod, I always use a bore guide. A bore guide is essentially a tube that’s (typically) inserted in the chamber to keep the cleaning rod as centered as possible when it is inserted down the barrel. There are many chamber bore guides out there, some universal to fit many types of (bolt) actions, but the best bore guide is one that is specifically designed to fit in your model gun.

For the AR-15, I currently use the Lucas Bore Guide. These are quite hard to come by, but the Lucas Bore Guides are highly renowned for design and quality. While a Lucas Bore Guide is created specifically for each action type (whether AR-15, Remington 700, Winchester model 70, etc), there is one specific feature that makes the Lucas Bore Guide special, and that’s the internal sleeve.

The Lucas Bore Guide is actually two-pieces, the main piece which goes into the action, and a second sleeve that is honed to a specified diameter to just allow your cleaning rod to pass through.

What this does is minimize the amount of lateral play of the cleaning rod even further, to eliminate the possibility the rod could bend/flex/bow and make contact with the throat or bore.

Thus, I have two sleeves for the Lucas bore guide, one for the diameter of my 20 caliber rod and one for my 22 caliber rod.

The reason why I use a 20cal rod and jag for patches is because I like to use 1-1/2″ Butch’s Bore Shine triple-twill patches. The 1-1/2″ square patches are actually meant for larger 6mm/.243″ bore diameters, while 22cal typically uses a 1″ patch. I don’t like 1″ patches because they don’t have much material to carry in solvent and to take out fouling on each pass. Plus, I found that even 1″ patches on a 22cal jag can be too tight, depending on the design of the jag used.

Pro-shot jag designs have a small head with a quick taper, which seems to mitigate the bunched up corners of a square patch around the jag.

That being said, I use a 1-1/2″ BBS triple-twill patch on a 20cal rod and jag in a .223/5.56 AR because it has a lot of patch material to deliver solvent and to wipe out fouling, and the combination of jag diameter and patch size is not too loose nor too tight in a .223/5.56 barrel.

For chamber cleaning, I use a Dewey CHR chamber cleaning rod. Two issues to note with the Dewey CHR. One is that it is a fixed handle, and it does not rotate freely. This is important since you want to be able to rotate the brush slightly when in the chamber. The second note is that the CHR is 8-32 female threaded. USGI M-16 chamber brushes are 8-36 threaded. 8-32 thread is pretty much the industry standard and the only time you’ll even use 8-36 accessories is with a USGI-style cleaning rod. Keep your life simple and stick to 8-32.

As far as other tools, I have a Brownells bolt carrier scraper. This hand tool basically helps you scrape the bottom/back of the bolt channel of the bolt carrier. It’s not perfect (and frankly, no bolt carrier scraper tool is), but I’ve always used it.

I also utilize a Sinclair cleaning cradle, but cleaning cradles are pretty much generic. All you need one for is to hold the rifle while you clean. You could theoretically use some sandbags to hold your rifle during cleaning, or even a front and rear shooting rest.

Supplies

- Butch’s Bore Shine 1-1/8″ and 1-1/2″ triple-twill patches

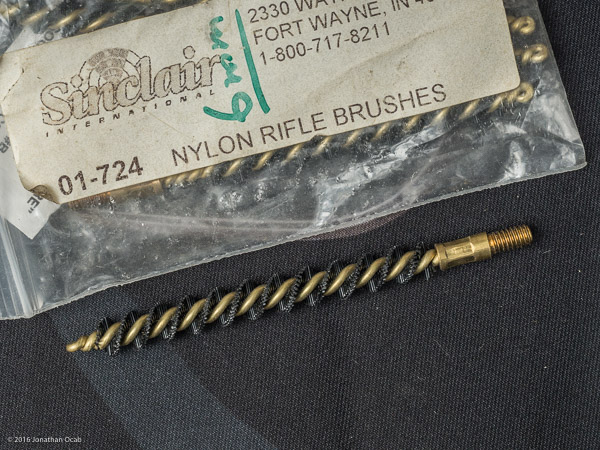

- Dewey (Pro Shot, Brownells, or Sinclair Intl.) 22 caliber bronze bristle, brass core bore brushes

- Dewey (Pro Shot, Brownells, or Sinclair Intl.) AR-15 chamber brushes

- Brownells AR-15 wool chamber mops

- Disposable shop towels (from any local home improvement store)

- GI-style general purpose duel end nylon brush

In the previous section regarding tools, I already discussed why I use specific sized patches. As far as why I specifically use Butch’s Bore Shine triple-twill patches, these are frankly the best patches I have ever used. I have gone through many brands of patches by cleaning supply manufacturers, house brands (e.g. Sinclair International), as well as the no-name gun show patches which were probably made out of cut up cotton t-shirts.

The BBS triple-twill patches are strong in that they don’t tear when you use them on a pierce-style jag. There are some cotton patches where the jag will just go completely through the patch when you try pierce the patch. Those generic cotton patches are better off for use on Parker Hale style jags (aka wrap jags) where you wrap the patch around the jag.

Anyway, BBS triple-twill patches also do a good job retaining solvent or oil and the texture of the patch seems to be able to wipe bores well.

Thus, I have been using the BBS triple-twill patches for the past 10 or so years now.

With regards to bore brushes, I am not stuck on any particular brand as long as they are well made and constructed using a brass core. Most of brushes you’ll find in the sporting goods section of a department store (and even sporting goods stores and some gun stores) are constructed using steel cores with bronze bristles. While the bristles are what make contact with the bore, the core itself can make contact with the throat or bore with improper cleaning techniques or if the brush wears out.

I prefer brass core brushes because it mitigates any possible damage to the barrel by the bore brush. Since you can get bronze bristle, brass core brushes in bulk for the same price, if not less, than the steel core brushes, there’s no reason not to buy brass core brushes.

I usually get them in 12-packs from Brownells or Sinclair Intl.

Note that I usually use bronze bristles for the AR, but I do own nylon bristle (brass core) bore brushes for other calibers, specifically for my bolt guns. Nylon is nice for when you actually use copper solvents, since copper solvents can eat bronze bristles. Since I use MPro-7 (carbon cleaner) in the barrel, I can get away with bronze bristle brushes which tend to scrub better than nylon.

Ironically enough, while I strenuously endorse the use of brass core bore brushes, the chamber brush and chamber mop I use have steel cores. Furthermore, the lug brushes of the chamber brush is also steel.

Pro-Shot does make brass core AR chamber brushes, though as far as I know, they only started doing this in recent years. But I would recommend going that route. Otherwise, you can just use the house brand Brownells AR chamber brushes, or any other AR chamber brush made by the cleaning supply manufacturer of your choice (e.g. Dewey, Tipton, Otis).

I use AR chamber mops made/sold by Brownells.

For general purpose brushing, I use the Gi-style dual end nylon brushes. You probably see these at surplus stores or gun shows.

These are pretty handy since you can wrap a paper / shop towel around the head on either end and insert that into the bolt carrier, in the charging handle channel of the upper receiver, etc., to wipe out hard to reach surfaces.

Solvents and Oils

- M-Pro7 Gun Cleaning Solution

- Montana X-Treme Bore Solvent

- Slip 2000 Extreme Weapons Lubricant (EWL)

- Slip 2000 Extreme Weapons Lubricant 30 (EWL30)

- Brake Cleaner (from any local auto parts store)

M-Pro7 Gun Cleaner has been my go to gun cleaning solution for a long time (15+ years). I use M-Pro7 on pretty much all of my guns. According to M-Pro7, their Gun Cleaner is non-water based, so you can soak parts in it without rusting directly caused by the solution. But what I like about M-Pro7 Gun Cleaner is that it is very good on carbon fouling, and is also why I use it to clean barrels before (if applicable) I use a copper solvent.

When I do need to address copper in a bore, I will use Montana X-Treme Bore Solvent. It is sold as a general purpose bore solvent, that can attack lead, carbon, and copper, but I have found it is more than adequate to get copper out of a bore, especially if you use M-Pro7 Gun Cleaner to get out all the carbon first.

Montana X-Treme makes another bore solvent called Copper Killer, which is their aggressive copper solvent. I have this in my cabinet, but I rarely ever use it. I would only use this in a barrel that I have found to be very problematic with copper fouling. You will never need this for an AR, especially one that has a chrome lined barrel.

I am currently using Slip 2000 Extreme Weapons Lubricant for the AR. It comes in two formulas, EWL and EWL30. EWL30 is basically the same as EWL30, but thicker (like the consistency of 30 weight motor oil). I will use EWL on the external surfaces of the rifle and in the bore (after cleaning), and EWL30 for the bolt carrier group and trigger group.

I know there’s a lot of controversy over what lubricant to use in an AR. Some people swear by Break-Free CLP, others by FrogLube, others by FireClean, etc. Some people even use regular motor oil. Frankly, I think as long as you use any gun lubricant, you should be fine.

I will say that for the AR-15 platform, I started off with Break-Free CLP. I moved away from Break-Free CLP for the internals, particularly the barrel, because I didn’t want to run a Teflon / Polytetrafluoroethylene (PTFE) based lubricant. PTFE solutions tend to attract grit and can cause build up. I actually experienced jams in my early days of shooting the AR with Break-Free CLP. What I found was that the CLP became very gritty due to the ammo and dust (outdoor range). I wiped it all off and it ran fine afterwards.

After a short while I then switched to Militec-1 (and Butch’s Bore Shine bore oil for the barrel), and then later to FrogLube (with Break-Free CLP for the external surfaces and BBS bore oil for the barrel).

I found myself cleaning my AR after a range session on a rainy day, and after I cleaned the gun in its entirety to displace all moisture (as well as the standard cleaning), I found myself trying to lubricate the internals with FrogLube and then all the externals with CLP (since it was stripped dry). I thought to myself it would be easier if I could just douse the rifle with a single lubricant / preservative and be done.

So that’s when I moved to Slip2000 EWL for all components for the AR. Slip2000 EWL is PTFE free, so I can use it in the bore (post-cleaning) as a rust preventative.

Granted, I do use two different EWL products, they’re both essentially the same, and I can actually just use EWL for the BCG as well. But I like to use EWL30 when I can on the BCG (and trigger group as needed) since it is thicker and won’t migrate as much when not in use.

Finally, I use standard brake cleaner you can find at your local auto parts store, mainly after cleaning with M-Pro7, and to remove any residual M-Pro7 to prep for lubrication.

That pretty much summarizes my cleaning tools and supplies.

I often come across people who inquire, “What cleaning kit should I buy?”

I’m not really a big fan of kits, since you might spend more for the items in the kit as a whole, rather than just buying the tools separately, and adding the supplies in bulk (e.g. brushes by the dozen). But if you want to go that route for your AR rifle to make things easier, I recommend getting the Dewey Complete AR-15 Cleaning Kit which comes with:

- 22c-36 – A 36 Inch Nylon Coated Rod

- 22J Brass Pointed Jag

- SMBA Brush Adaper

- M16B Breech Rod Guide

- B22 Bore Brush

- P-171 Cotton Flannel Patches

- ARL Link Cleaning Pin

- L-16 Chamber Cleaning Kit

As you acquire more firearms of different cartridges and calibers, you’ll also need to acquire more cleaning rods and bore guides (as applicable) to accommodate those firearms. I have about a dozen different cleaning rods for pistols and rifles.

Again, this the firearms cleaning series of articles I am posting are meant to provide information from my point of view and how I approach firearms cleaning. Since I am a proponent of using cleaning rods, that’s why I discuss them at length. That is not to say the pull through type cleaning tools like the Otis kits are not good, but cleaning rods are a lot easier (unless you’re actually “in the field” and can’t carry a rod). You may elect to use the same lubricant I use, or maybe you prefer something else; as long as you keep your AR-15 lubricated.

Comment on this post